ENGINEERED FIRST.

ENGINEERED TO LAST.

ENGINEERED FIRST.

ENGINEERED TO LAST.

What is Composite Body Solutions™ (CBS™) reinforcement technology?

Optimizing Strength, Stiffness and Weight

L&L Products’ Composite Body Solutions™ (CBS™) technology offers innovative solutions that help manufacturers address critical challenges related to weight reduction, structural integrity, EV integration, NVH management, manufacturing efficiency, and sustainability.

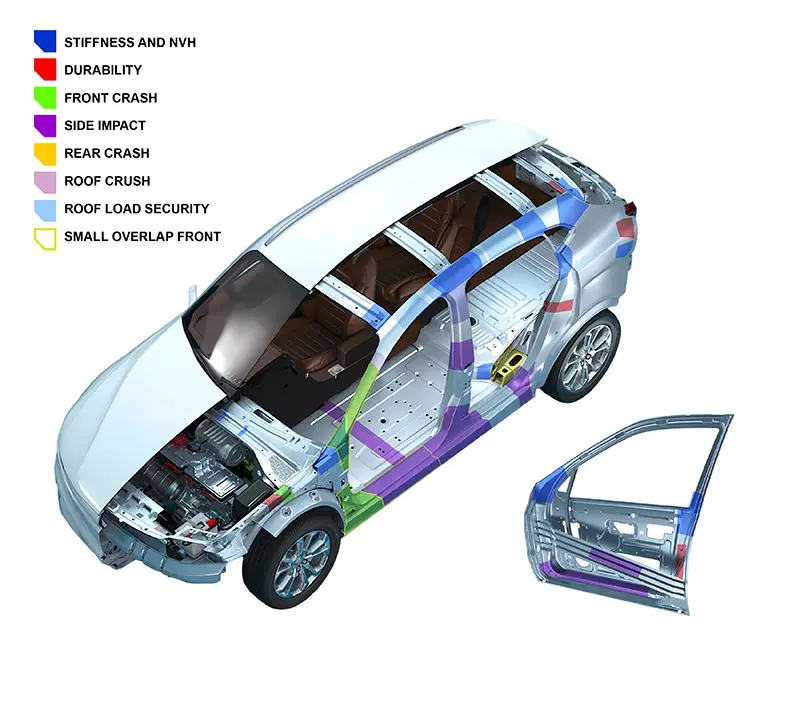

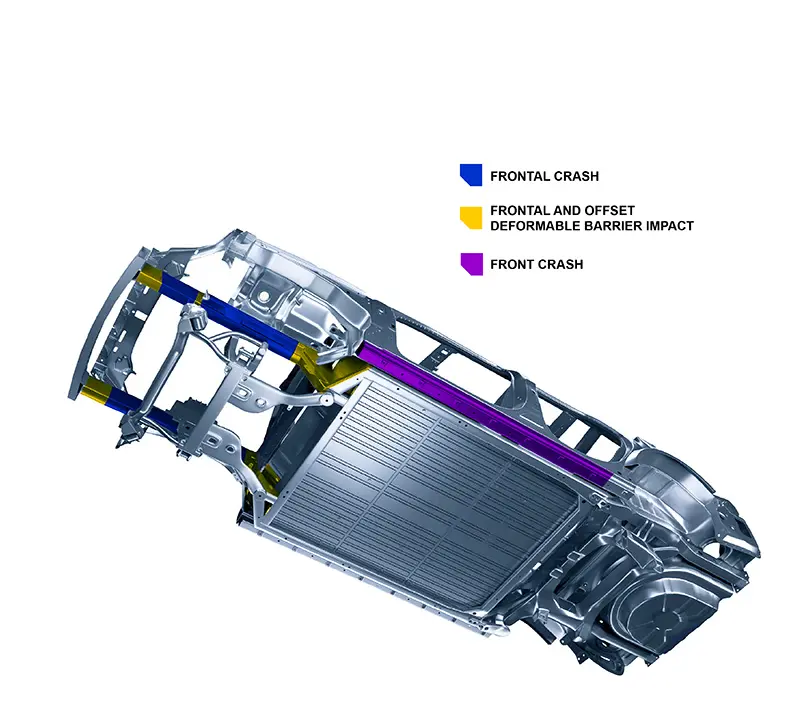

First introduced almost 30 years ago, CBS™ reinforcements combine a proprietary heat-activated structural adhesive (structural foam) with a metal, thermoplastic, thermoset, or hybrid carrier to create lightweight, strong structural reinforcements that reduce vehicle weight, increase stiffness for NVH applications, improve crashworthiness, and increase vehicle durability.

The L&L Products team uses its decades of proven expertise with advanced CAD/CAE simulation tools to design three-dimensional engineered parts. The result is a custom-engineered structural insert that is dry-to-the-touch and ready to assemble into the body-in-white before cavity closure and E-coating.

- Dry-to-the-touch parts, ready for assembly

- Compatible with traditional and low-temperature bake

- E-coat body processes

- Optimized through advanced CAD/CAE simulations

- Advanced production and molding techniques

Discover.

Performance

- High stiffness-to-weight ratio

- Load path management

- Section integrity and stability of joints

- Increased durability and rigidity

Lightweight

- Enables thickness reduction and part replacement for potential lightweighting

NVH

- Increased rigidity for reduced vibration

- Improved NVH performance

Process

- Seamless integration in the BIW process

- Ease of assembly

- Reduced implementation timing

- No impact to the body shop

Expertise

- Custom-engineered solutions

- In-house engineering expertise

- Decades of accumulated expertise

Cost

- Cost-efficient per weight saved

- Competitive with traditional metal reinforcements, often at neutral or reduced cost

PRODUCT ADVANTAGES.

Composite Body Solutions™ (CBS™) reinforcements enable optimized reinforcement, bonding, and part design with the right amount of material at the right position.

Stable Cross-Section Geometry

CBS™ technology enables four-sided bonding, ensuring structural stability and optimized reinforcement exactly where needed.

Benefit: Maintains cross-sectional integrity for reliable performance.

Bonding with Tolerance Management

Our proprietary adhesives adapt to assembly tolerances by foaming during activation—ensuring secure bonding even in complex geometries.

Benefit: Ensures robust bonding despite assembly variations.

Predictable, Validated Performance

Our global engineering teams use eight CAE tools, three CAD platforms, and comprehensive prototyping to ensure high predictability, manufacturability, and optimized performance.

Benefit: Delivers optimized parts through simulation-driven design with decades of experiential inputs.

Potential Applications.

Our highly experienced engineering team works with our customers to design the CBS™ parts to meet the specific application requirements.

Applications include

- EV BIW Architectures

- Vibration Acoustics Improvement

- Door and Closure Applications

- Crash and Impact Management

IN AUTOMOTIVE

CBS™

IN COMMERCIAL VEHICLES

CBS™

IN BUS

Resources.

Download our resources to find out more about Composite Body Solutions™ reinforcement technology.